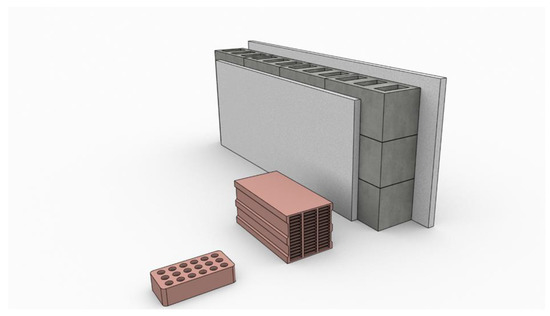

CMU block filling with insulative materials drastically improves thermal performance by reducing heat transfer through masonry walls by up to 75% compared to unfilled blocks. The most effective options include foam inserts (R-values of 4.0-13.5 per inch), perlite/vermiculite fills (R-values of 2.5-3.8), and polyurethane injections (R-values of 6.0-7.0 per inch). Each material creates thermal breaks within block cavities, significantly enhancing building envelope efficiency while maintaining structural integrity.

Optimal Materials for CMU Block Insulation

Different filling materials deliver varying thermal performance levels based on their composition and installation method. Select materials based on climate zone requirements, budget constraints, and performance objectives.

| Material | R-Value Per Inch | Installation Complexity | Moisture Resistance | Lifespan (Years) |

| EPS Foam Inserts | 4.0-4.5 | Low | Moderate | 50+ |

| XPS Foam Inserts | 5.0-5.5 | Low | High | 50+ |

| Polyisocyanurate | 6.0-7.5 | Medium | Moderate | 30-50 |

| Spray Polyurethane | 6.0-7.0 | High | High | 30+ |

| Loose-Fill Perlite | 2.5-3.0 | Medium | Low | 50+ |

| Vermiculite | 2.7-3.8 | Medium | Low | 50+ |

| Mineral Wool | 3.0-3.3 | Medium | High | 50+ |

Bonus Tip: When using foam inserts, stagger them within block cavities to eliminate thermal bridging at seams, increasing overall wall R-value by 10-15%.

Installation Methods and Performance Impact

The installation technique significantly influences thermal performance outcomes, with each method offering distinct advantages for different project requirements.

Pre-Filled Block Systems

Pre-insulated blocks arrive with insulation already integrated, saving on-site labor costs and ensuring consistent performance. These systems typically incorporate molded foam inserts precisely fitted to block cavities, delivering R-values of 5.0-11.0 for the complete wall assembly.

Field-Installed Inserts

Field installation involves placing rigid foam inserts into CMU cells during wall construction. This method allows flexibility in material selection but requires careful coordination with masons to ensure proper placement.

Post-Construction Injection

For retrofit applications, drilling access points and injecting foam or loose-fill materials into existing walls offers an effective solution. This method typically achieves 85-95% cavity fill rates when performed by experienced contractors.

Technical Performance Metrics

When evaluating CMU Block insulation systems, several key performance metrics determine real-world effectiveness beyond simple R-value calculations.

| Performance Metric | Definition | Importance | Target Values |

| Effective R-Value | Total thermal resistance including air films and thermal bridging | Primary energy efficiency indicator | 8.0-16.0 for complete wall assembly |

| Thermal Mass Effect | Heat storage capacity of masonry system | Reduces temperature fluctuations | 8-12 BTU/ft²·°F for filled CMU walls |

| Air Infiltration Rate | Air leakage through assembly | Critical for preventing moisture issues | <0.25 cfm/ft² at 75 Pa pressure |

| Vapor Permeability | Rate of water vapor transmission | Moisture management capability | 0.1-10 perms depending on climate zone |

| Sound Transmission Class (STC) | Acoustic insulation performance | Occupant comfort | 45-55 STC for filled CMU walls |

| Fire Resistance Rating | Time assembly resists standard fire exposure | Building code compliance | 2-4 hours depending on block thickness |

Recent market data indicates that buildings with properly insulated CMU walls experience 28-35% reductions in annual heating and cooling costs compared to uninsulated masonry construction, with a typical payback period of 3-7 years depending on local energy costs.

Climate-Specific Applications

Different climate zones require specialized approaches to CMU insulation to address local conditions effectively.

Cold Climate Strategies

In regions with heating degree days exceeding 5,400, focus on maximizing R-value through:

- Full-cavity polyisocyanurate or closed-cell spray foam (minimum R-13 total wall)

- Continuous exterior insulation supplementing cavity fills

- Addressing thermal bridging at bond beams and lintels

Hot-Humid Climate Approaches

For areas with cooling degree days above 3,000 and high humidity:

- Moisture-resistant fills like closed-cell foam

- Vapor-permeable materials toward the exterior

- Thermal mass optimization through high-density fills

Bonus Tip: In hot-humid climates, select fills with perm ratings below 1.0 on the interior side of the wall to prevent condensation within block cavities during mechanical cooling periods.

Things to Consider Before Making a Decision

Structural Implications

Filling CMU blocks impacts structural properties in several ways:

- Grout-filled cells for structural reinforcement must remain insulation-free

- Some lightweight fills may provide minimal additional compressive strength

- Freeze-thaw durability improves with moisture-resistant fills

- Bond between fill material and block interior affects long-term performance

Code Compliance Requirements

Modern building codes typically specify:

- Minimum R-values based on climate zone (IECC/ASHRAE 90.1)

- Fire resistance ratings for specific occupancy types

- Special provisions for below-grade applications

- Documentation requirements for material performance

Installation Timing and Sequencing

Coordination with construction schedule affects outcomes:

- Pre-filled systems require early specification but reduce field labor

- Insert installation must align with masonry work

- Injection fills require wall completion and curing before application

- Weather conditions during installation impact adhesion and curing

Cost-Benefit Analysis

While initial costs vary significantly between insulation methods, long-term performance delivers substantial returns on investment.

| Insulation Type | Initial Cost | Annual Energy Savings | Maintenance Requirements | Lifecycle Cost (30 yr) |

| EPS Inserts | Medium | 25-30% | None | Low |

| XPS Inserts | Medium-High | 30-35% | None | Low-Medium |

| Polyisocyanurate | High | 35-40% | None | Medium |

| Spray Polyurethane | High | 35-45% | None | Medium |

| Loose Fill (Perlite) | Low | 20-25% | Possible settling | Medium-High |

| Integrated Systems | Very High | 40-50% | None | Medium |

Industry analysts report that buildings utilizing optimized CMU insulation systems have demonstrated 18-22% higher property valuations compared to similar structures with basic masonry construction, particularly in markets emphasizing energy performance certifications.

Topic FAQ

What R-value does an insulated CMU wall actually achieve?

A properly insulated 8-inch CMU wall typically achieves effective R-values between 8.0-16.0, depending on the fill material, installation quality, and whether supplemental insulation layers are present. This represents a 300-500% improvement over unfilled blocks.

Can insulation be added to existing CMU walls?

Yes, retrofit insulation through injection methods works effectively for existing walls. The process involves drilling small access holes (typically 5/8″ to 1″) into mortar joints or blocks, injecting insulation material, and patching the holes. Success rates depend on wall condition and contractor expertise.

How does filled CMU compare to other wall systems?

Insulated CMU walls offer superior thermal mass benefits compared to frame construction, providing better temperature stabilization and peak load shifting. While lightweight systems may achieve higher nominal R-values, the effective performance of filled CMU often delivers better real-world energy efficiency in many climate zones.

Do filled CMUs still require additional insulation layers?

In cold climates (zones 5-8), supplemental continuous insulation remains beneficial despite cavity filling. For moderate climates (zones 3-4), properly filled CMUs often satisfy code requirements without additional layers. Always verify specific requirements with local building officials.

How do insulated CMUs affect construction schedules?

Pre-insulated blocks and inserts installed during masonry work add minimal time to construction schedules. Post-construction injection typically requires 1-3 days for an average commercial building but necessitates coordination with other trades for access.

Maximize Your CMU Wall Performance

The superior insulation performance of filled CMU blocks delivers significant benefits throughout a building’s lifecycle. By selecting appropriate materials based on climate conditions, moisture exposure, and performance requirements, designers can transform basic masonry construction into high-performance building envelopes.

For optimal results, combine cavity fills with attention to mortar joint quality, flashing details, and proper integration with fenestration. Consider the building’s entire thermal envelope performance rather than focusing solely on wall assembly R-values.

Evaluate your specific project requirements carefully, consulting with masonry specialists familiar with advanced insulation techniques to develop a comprehensive solution that balances initial costs with long-term performance benefits.

Reviewer:

Charlotte King reviewed this article based on her 7 years of spray foam experience, contributing thoughtful advice about building customer relationships and improving local visibility.