In today’s competitive industrial landscape, businesses across diverse sectors demand high-quality, precision-engineered components to meet specific requirements. Whether it’s for automotive, medical, electronics, or consumer goods, the need for custom injection molding parts has become more crucial than ever. Partnering with a trusted custom injection molding parts manufacturer can significantly impact your product’s quality, functionality, and overall market success.

This blog explores why finding a reliable partner is essential and what sets a trusted custom injection molding parts manufacturer apart from the competition.

What Is Custom Injection Molding?

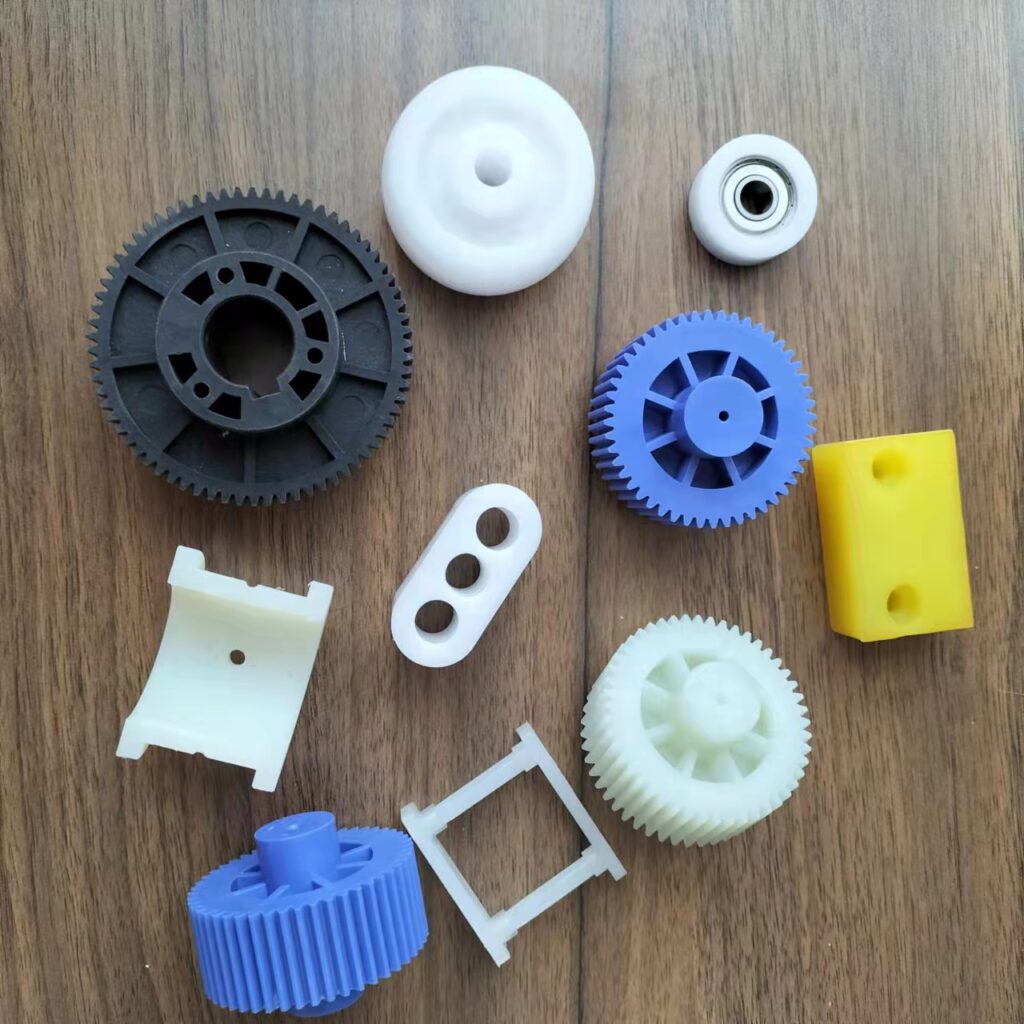

Custom injection molding is a manufacturing process used to produce intricate and highly precise plastic components tailored to meet specific client requirements. This process involves melting thermoplastic or thermoset materials, injecting them into a custom-designed mold, and cooling them to create the desired shape. Customization ensures that the resulting parts align perfectly with the client’s design, material, and performance specifications.

From small, complex components to large, durable parts, custom injection molding provides flexibility and reliability, making it a preferred choice for industries worldwide.

The Importance of Choosing the Right Partner

When it comes to custom injection molding, selecting the right manufacturer can make all the difference. A trusted partner ensures that your product is manufactured with precision, quality, and efficiency. Here are a few reasons why the right partner is indispensable:

- Expertise and Innovation A reliable manufacturer brings years of experience and technical expertise to the table. They leverage advanced technologies and innovative approaches to meet even the most complex design and production challenges.

- High-Quality Standards Trusted manufacturers adhere to strict quality control measures throughout the injection molding process. From material selection to final inspection, every step is meticulously monitored to ensure exceptional results.

- Cost-Effectiveness Partnering with a reliable custom injection molding manufacturer can help reduce costs. Their efficiency in production, waste reduction, and material optimization translates to savings for your business.

- Tailored Solutions A trusted partner works closely with you to understand your unique requirements. They provide tailored solutions, ensuring the final product meets your specifications and exceeds your expectations.

- On-Time Delivery Delays in production can impact your project timeline and profitability. A dependable manufacturer prioritizes timely delivery, keeping your operations on track.

Key Features of a Trusted Custom Injection Molding Manufacturer

So, what should you look for in a trusted custom injection molding parts manufacturer? Here are some key features that distinguish industry leaders:

1. Advanced Manufacturing Capabilities

A trusted manufacturer invests in state-of-the-art machinery and equipment to handle complex designs and large-scale production runs. This includes high-precision injection molding machines, automated systems, and advanced mold-making technology.

2. Material Expertise

Understanding the properties of various materials is crucial for creating durable and functional components. A reliable manufacturer offers expertise in working with a wide range of plastics, including: • Polycarbonate (PC)

• Acrylonitrile Butadiene Styrene (ABS)

• Polyether Ether Ketone (PEEK)

• Ultra-High-Molecular-Weight Polyethylene (UHMWPE)

• Nylon, and more.

They can guide you in selecting the best material based on your application’s mechanical, chemical, and thermal requirements.

3. Design and Prototyping Support

The best manufacturers offer design and prototyping support to help you refine your product concept. Using computer-aided design (CAD) software and rapid prototyping techniques, they can test and validate your design before full-scale production, reducing errors and ensuring optimal performance.

4. Quality Assurance

Quality is non-negotiable when it comes to injection molding. A trusted partner implements rigorous quality assurance protocols, including: • Dimensional inspection

• Material testing

• Functionality tests

• Certifications such as ISO 9001 and industry-specific compliance.

These measures guarantee that every part meets stringent quality standards.

5. Scalability and Flexibility

A reliable manufacturer can handle projects of varying sizes, from small batch production to high-volume orders. They also offer flexibility to accommodate changes in design, production schedules, or material requirements.

Applications of Custom Injection Molding Parts

Custom injection molding parts play a critical role in a wide range of industries. Some common applications include:

1. Automotive Industry

• Engine components

• Interior and exterior trims

• Safety features such as airbag housings.

2. Medical Devices

• Surgical instruments

• Diagnostic equipment

• Drug delivery systems.

3. Consumer Electronics

• Enclosures and casings

• Connectors

• Circuit board components.

4. Industrial Equipment

• Gears and bearings

• Custom machine parts

• Seals and gaskets.

5. Packaging Industry

• Caps and closures

• Containers

• Specialty packaging solutions.

Why Choose Petron Thermoplast?

At Petron Thermoplast, we pride ourselves on being a trusted partner for custom injection molding parts. With decades of experience and a commitment to excellence, we deliver solutions that meet the unique needs of our clients.

What Sets Us Apart?

- Comprehensive Services We offer end-to-end injection molding solutions, including design, prototyping, mold manufacturing, production, and assembly.

- Industry Expertise Our team has extensive experience working with industries such as automotive, medical, electronics, and more.

- Cutting-Edge Technology Our advanced facilities are equipped with the latest injection molding machines and quality control systems.

- Customized Solutions We work closely with clients to create tailored solutions that align with their goals and specifications.

- Sustainability We prioritize eco-friendly practices, including material recycling and energy-efficient manufacturing processes.

Conclusion

Choosing the right custom injection molding parts manufacturer is a critical decision that can influence your product’s success. A trusted partner like Petron Thermoplast ensures you receive high-quality, precision-engineered parts that meet your unique requirements. From design and prototyping to production and delivery, we are committed to excellence every step of the way.

Contact us today to discuss your custom injection molding needs and discover how we can bring your vision to life.