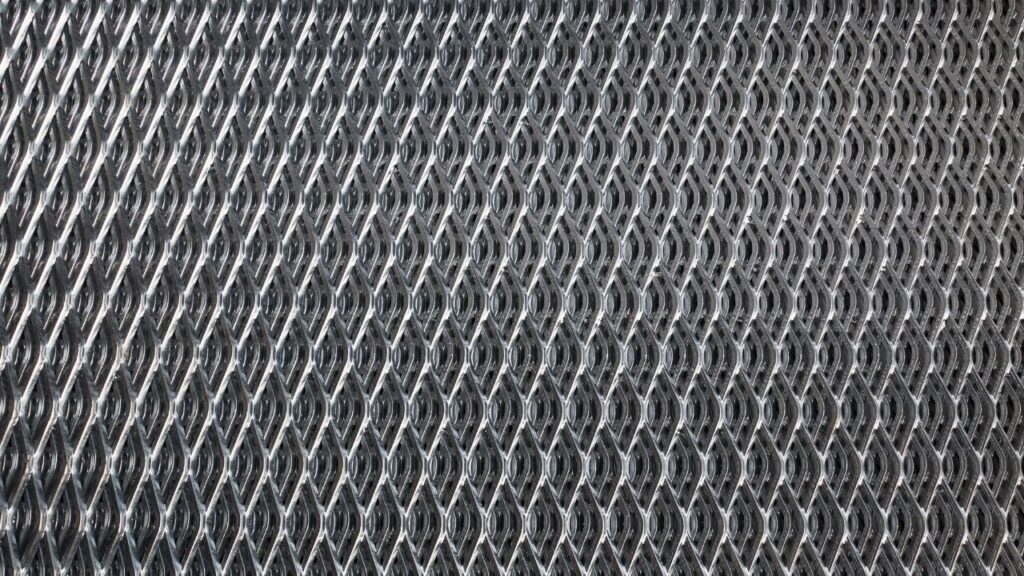

When it comes to selecting durable, cost-effective materials for construction, fencing, and industrial applications, galvanised mesh stands out as the clear winner. Whether you’re a contractor, architect, or DIY enthusiast, understanding the advantages of galvanised wire mesh can save you time, money, and countless headaches down the road.

What Makes Galvanised Mesh Superior?

Galvanised weld mesh isn’t just regular wire mesh with a fancy coating—it’s a engineered solution designed to withstand Australia’s harsh climate conditions. The galvanisation process involves applying a protective zinc coating to steel wire, creating a barrier that prevents rust and corrosion for decades.

This protective coating extends the lifespan of welded wire mesh by providing a strong barrier against wear and tear, making it suitable for high-stress applications such as construction reinforcements and industrial fencing. In environments where moisture, salt air, and temperature fluctuations are constant challenges, this protection becomes invaluable.

The Science Behind Long-Lasting Protection

The galvanisation process creates multiple layers of protection. When steel wire is hot-dip galvanised, it forms an alloy layer between the steel and zinc coating that bonds at the molecular level. This isn’t just a surface treatment—it’s a metallurgical transformation that provides:

- Corrosion resistance lasting 15-25 years in most Australian conditions

- Self-healing properties where minor scratches automatically protect themselves

- Uniform coverage ensuring every part of the wire receives protection

- Impact resistance that maintains integrity under stress

Versatile Applications Across Industries

Construction and Reinforcement

Galvanised wire mesh serves as concrete reinforcement in driveways, footpaths, and structural elements. Its consistent grid pattern ensures even load distribution while the galvanised coating prevents the rust-related expansion that can crack concrete over time.

Security and Fencing

From residential boundary fences to high-security installations, galvanised weld mesh provides the perfect balance of visibility, strength, and longevity. The low maintenance requirements make it ideal for applications where ongoing upkeep would be costly or difficult.

Agricultural Solutions

Livestock enclosures, crop protection, and ventilation systems all benefit from galvanised mesh’s combination of strength and weather resistance. The smooth galvanised surface won’t snag on clothing or injure animals, making it safer than many alternatives.

Industrial and Commercial Use

Manufacturing facilities, warehouses, and commercial buildings use galvanised wire mesh for machine guards, storage area separation, and ventilation panels. Due to its attractive price point and corrosion resistance, galvanised wire mesh is popular among industrial users.

Installation Best Practices for Maximum Performance

Getting the most from your galvanised mesh investment starts with proper installation:

Foundation Preparation

- Ensure posts are properly aligned and set at appropriate depths

- Use galvanised fixings to prevent galvanic corrosion

- Allow for thermal expansion in large installations

Attachment Methods Attach welded mesh every 15cm to keep it secure, with loose connections allowing movement during temperature changes and impact. This flexibility prevents stress concentration that could lead to failure.

Cutting and Handling When cutting galvanised wire mesh, protect cut ends with galvanised spray or zinc-rich primer to maintain corrosion resistance at vulnerable points.

Maintenance: Simple Steps for Decades of Service

One of the greatest advantages of galvanised mesh is its minimal maintenance requirements. However, a simple maintenance routine can extend its life even further:

Regular Inspection Periodic inspections are advisable, especially after extreme weather conditions, checking for signs of wear or damage and making necessary adjustments.

Basic Cleaning Clean the surface every six months with warm water and mild soap, using a soft cloth and wiping dry after washing. This removes salt deposits and contaminants that could accelerate corrosion.

Damage Response Address any damage promptly by cleaning affected areas and applying zinc-rich primer or galvanised spray to maintain protection.

Cost-Effectiveness That Speaks Volumes

While the initial cost of galvanised mesh might be higher than basic steel alternatives, the long-term value proposition is compelling:

- Reduced replacement costs due to extended lifespan

- Lower maintenance expenses compared to painted or untreated alternatives

- Consistent performance without degradation over time

- Retained property value through durable, professional-grade installations

Wire mesh provides robust structural support and longevity while offering an affordable solution that can be tailored to meet specific project requirements.

Choosing the Right Supplier

When selecting galvanised mesh for your project, partner with suppliers who understand Australian conditions and provide:

- Australian Standard compliance ensuring quality and performance

- Comprehensive sizing options to minimize waste and maximize efficiency

- Technical support for installation and application guidance

- Reliable delivery to keep your project on schedule

Environmental Considerations

Galvanised mesh offers significant environmental advantages:

- Longevity reduces replacement frequency, minimizing environmental impact

- Recyclable materials support circular economy principles

- Energy-efficient production compared to alternative protective coatings

- Reduced maintenance means fewer chemicals and resources used over time

Future-Proofing Your Investment

As building codes become more stringent and environmental considerations more important, galvanised mesh positions your projects for long-term success. Its proven performance record, combined with ongoing improvements in galvanising technology, ensures that choosing galvanised wire mesh today means making a decision that will prove wise for decades to come.

Making the Smart Choice

Whether you’re planning a small residential project or a major commercial installation, galvanised mesh offers the reliability, durability, and value that Australian conditions demand. The combination of superior corrosion protection, structural integrity, and cost-effectiveness makes it the logical choice for discerning professionals and property owners.

Don’t let inferior materials compromise your project’s success. Choose galvanised weld mesh and galvanised wire mesh solutions that deliver lasting performance, exceptional value, and peace of mind. Your future self will thank you for making the smart choice today.

Read Also: The Benefits of Wire Netting for Your Plants