Membrane roofing systems offer distinct advantages when it comes to improving energy performance in commercial and residential buildings. Their ability to reflect solar heat, prevent air leakage, and support long-term thermal stability has positioned them as a practical choice in regions focused on reducing energy costs and improving envelope durability.

This article explores how membrane roofs contribute to energy efficiency, the types available, performance differences, and what building owners should understand when evaluating their insulation and roofing upgrade strategies.

How Membrane Roofing Contributes to Energy Savings

A Professional membrane roofing company improves energy performance by ensuring minimized heat transfer and preventing air and moisture intrusion. These factors directly influence HVAC demand and interior comfort.

Thermal Resistance and Insulation Support

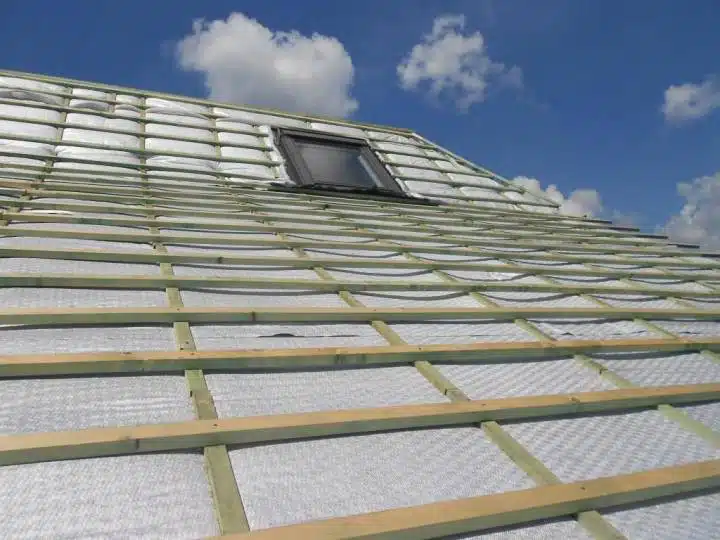

- Membrane systems, especially single-ply types like TPO and PVC, often work in conjunction with insulation layers (polyiso, EPS, or mineral wool).

- This pairing reduces conductive heat gain and loss, lowering seasonal heating and cooling requirements.

Reflective Surface Properties

- Light-colored membranes, particularly white TPO and PVC, reflect up to 80% of solar radiation.

- Lower roof surface temperatures reduce indoor heat gain, especially beneficial in warm climates or during summer months.

Air and Vapor Barrier Function

- Membranes act as air and vapor control layers, minimizing infiltration and exfiltration.

- This function supports HVAC system efficiency and preserves the building’s thermal gradient.

Key Types of Membrane Roofing Systems and Their Energy Features

Each membrane type offers distinct energy-related performance characteristics based on material composition, reflectivity, and installation method.

Thermoplastic Polyolefin (TPO)

TPO membranes are among the most reflective roofing options, widely adopted for their energy-saving potential.

- UV-resistant and heat-reflective surface

- Welded seams reduce air leakage risks

- High emissivity supports faster heat release

Polyvinyl Chloride (PVC)

PVC roofing shares many reflective traits with TPO but includes added chemical resistance.

- Effective in commercial buildings with vent stacks or exhausts

- High solar reflectivity helps reduce peak cooling loads

- Compatible with vegetative roofing strategies

Ethylene Propylene Diene Monomer (EPDM)

EPDM membranes are durable but typically come in darker colors unless custom-ordered.

- Offers longevity and flexibility in colder climates

- Lower reflectivity unless white EPDM is selected

- Best when paired with thick insulation underlayment

Modified Bitumen and Built-Up Roofing (BUR)

While more traditional, these systems can still support efficiency through insulation layering.

- Often combined with rigid foam insulation

- May require surface coatings to improve reflectivity

- Best suited for buildings needing redundancy or impact resistance

Factors Affecting Energy Efficiency in Membrane Installations

Installing a membrane roofing system involves several performance-critical variables that affect thermal output, moisture control, and insulation synergy.

Roof Color and Surface Reflectance

- Lighter membranes reflect solar energy and reduce heat absorption.

- Darker membranes may be more suitable in cold-dominant climates but increase cooling costs.

Insulation Integration

- Using tapered insulation improves drainage and reduces ponding risks while supporting thermal resistance.

- Polyiso is commonly used due to its high R-value per inch.

Attachment Method and Airtightness

- Fully adhered systems offer superior air barrier performance compared to mechanically attached ones.

- Hot-air welded seams in TPO/PVC reduce the chance of seam failure, enhancing energy savings.

Comparison Table: Membrane Roofing Types by Energy Features

| Membrane Type | Reflectivity | Seam Type | Insulation Compatibility | Best Climate Fit | Energy Efficiency Benefit |

|---|---|---|---|---|---|

| TPO | High | Heat-welded | High | Warm/Mixed | Excellent |

| PVC | High | Heat-welded | High | Warm/Industrial | Excellent |

| EPDM (Black) | Low | Adhesive/Taped | High | Cold | Moderate |

| EPDM (White) | Moderate | Adhesive/Taped | High | Mixed | Good |

| Modified Bitumen | Moderate | Torch/Cold-applied | Medium | Mixed/Cold | Fair |

Long-Term Energy and Cost Impacts of Membrane Roofing

Beyond immediate utility savings, membrane roofs contribute to lifecycle cost reductions through performance durability and reduced HVAC strain.

Reduced HVAC Load and Equipment Cycling

- Lower heat gain means systems cycle less frequently, reducing wear.

- Buildings maintain more stable interior temperatures with less fluctuation.

Reduced Urban Heat Island Contribution

- High-SRI membranes contribute to reduced ambient heat in urban environments.

- This effect lowers peak energy demand in surrounding infrastructure.

Maintenance and Durability Factors

- Seam integrity and membrane resistance to UV and punctures reduce leak-related energy loss.

- With proper installation, membrane systems can last 20–30 years while maintaining performance metrics.

What Building Owners Should Consider When Evaluating Membrane Systems

Owners and property managers should focus on how membrane options align with building goals, climate demands, and retrofit opportunities.

Climate Compatibility

- High-reflective systems like TPO/PVC are optimal for sun-dominant regions.

- Black EPDM or insulated modified bitumen may suit heating-dominant zones.

Retrofit Versus New Construction

- Retrofitting membrane roofing on existing insulation layers can improve performance without structural changes.

- Replacing the full roof system may allow for improved thermal performance with new high-R insulation layers.

Roofing Warranty and Service Life

- Energy-efficient performance is only as reliable as membrane durability.

- Choose systems with tested aging and weather resistance backed by long-term warranties.

Common Question

How does membrane roofing reduce summer cooling costs? Reflective membranes block solar radiation before it penetrates the roof assembly. This reduces roof surface temperatures, lowering heat transfer into the interior and decreasing the need for air conditioning.

Conclusion

Membrane roofing systems serve as both protective and energy-conserving layers in commercial and residential structures. Their value extends beyond weather resistance, directly impacting long-term energy use, interior comfort, and HVAC system longevity. When selected with climate and insulation compatibility in mind, these systems offer consistent thermal benefits and measurable cost reductions.

Building owners looking to lower operational costs while improving building performance before hiring a professional insulation contractor, one should evaluate membrane options based on reflectivity, air control, and insulation synergy. Whether for new builds or energy-efficient retrofits, membrane systems remain a reliable choice for improved envelope performance.

FAQs

What is the most energy-efficient membrane roofing material? TPO and PVC are considered the most energy-efficient due to their high solar reflectance and emissivity. These traits help reduce rooftop heat gain and cooling loads.

Does a membrane roof need additional insulation? Yes. Membranes function best when paired with high-R-value insulation such as polyiso, helping meet energy code requirements and boosting thermal performance.

Can membrane roofs be installed over an old roof? Yes, in many cases. Re-cover systems can be installed over existing roofing with a cover board and insulation layer, assuming the deck is in good condition.

How long do energy-efficient membrane roofs last? Properly installed membrane roofs can last 20–30 years. Performance longevity depends on maintenance, climate exposure, and material quality.

Do white roofs lower building temperature year-round? White membranes are most effective during hot seasons. In colder climates, the benefit may be less noticeable or balanced by increased heating demand unless insulation compensates.

Reviewer: Lily Johnson offered her feedback after reviewing this post. With 8 years in the spray foam insulation field, her suggestions centered around improving outreach to homeowners looking for quality insulation solutions.