In today’s industrial landscape, the demand for durable, cost-effective, and versatile materials has grown significantly. One such product that has consistently proven its value across various sectors is the chequered plate. Known for its distinctive raised pattern and robust construction, this metal sheet is used in a variety of applications ranging from flooring and transportation to construction and manufacturing. But with evolving technologies and new materials entering the market, one may ask — Is it worth investing in chequered plates now?

This article delves deep into the characteristics, benefits, and current market relevance of chequered plates to help you make an informed decision.

Understanding What Chequered Plates Are

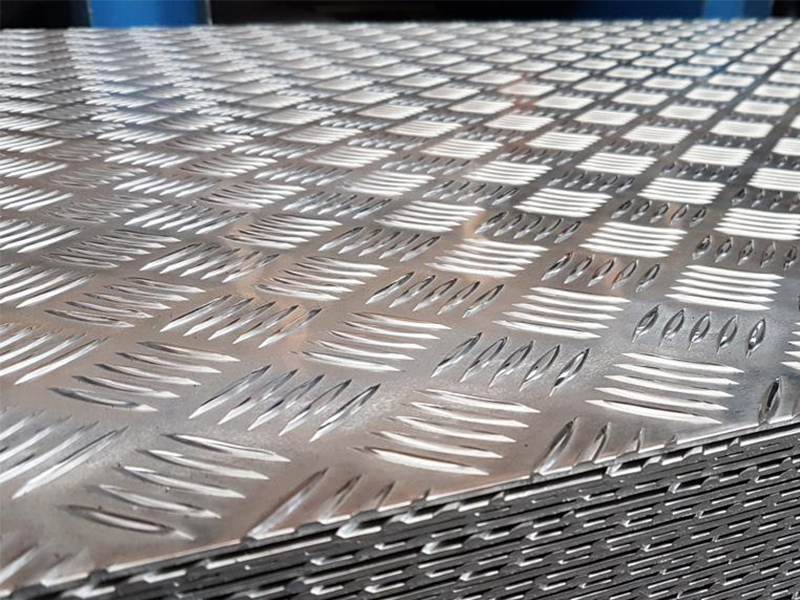

Chequered plates, also known as tread plates or checker plates, are metal sheets with a regular pattern of raised lines or diamonds on one side. The raised texture provides additional grip and reduces the risk of slipping, which makes it ideal for flooring, ramps, stair treads, and industrial platforms.

These plates are typically made from metals such as steel, stainless steel, and aluminum. Depending on the intended application, each type offers unique benefits in terms of strength, corrosion resistance, and weight.

The Current Market Demand for Chequered Plates

Over the past few years, infrastructure and industrial developments have surged globally, especially in the Middle East, Africa, and Southeast Asia. Countries focusing on transportation infrastructure, renewable energy, and high-rise construction have led to an increased need for strong, versatile materials like chequered plates.

Chequered Plates in Dubai, for example, has seen a sharp rise in demand for high-performance construction materials. From metro projects to commercial buildings and pedestrian walkways, chequered plates are being widely adopted due to their load-bearing capacity and anti-slip properties.

Key Advantages of Chequered Plates

To determine if it’s worth investing in chequered plates now, one must understand their primary benefits:

High Strength and Durability

Chequered plates are manufactured using high-grade metals, making them exceptionally durable. They can withstand heavy weights and pressure, making them ideal for high-traffic areas, platforms, and industrial flooring.

Anti-Slip Surface

The raised pattern provides excellent slip resistance, even in wet or oily environments. This safety feature is crucial in sectors such as construction, marine, and transportation.

Aesthetic and Functional Appeal

Beyond utility, chequered plates also add an industrial, rugged aesthetic to interiors and exteriors, particularly in commercial and retail spaces. Their unique look and reflective surface enhance both safety and style.

Versatility Across Industries

These plates are used in numerous sectors:

- Automotive: For flooring and tailgates in trucks and trailers.

- Construction: For staircases, walkways, and scaffolding.

- Marine: In ship decks and docks due to their resistance to corrosion.

- Aviation: In hangars and maintenance platforms.

Economic Viability and Return on Investment

When compared to other flooring or surface materials, chequered plates offer a balanced mix of affordability and performance. Their long life cycle, low maintenance, and high load resistance make them a cost-effective solution for both small and large-scale projects.

Additionally, given the global trend toward safety-compliant infrastructure, materials that provide enhanced grip and structural integrity — like chequered plates — are becoming increasingly sought-after.

Environmental Impact and Sustainability

In the context of growing sustainability concerns, chequered plates also offer environmentally friendly options. Aluminum and steel chequered plates are recyclable, reducing overall material waste. Companies can resell or recycle used plates rather than dispose of them, aligning with green construction practices.

Moreover, modern manufacturing processes for chequered plates have become more energy-efficient and less polluting, making their production more sustainable than ever before.

Technological Innovations in Chequered Plate Production

Recent advancements in fabrication techniques have allowed for more precise and consistent pattern formation on chequered plates. Laser cutting, CNC machining, and automated rolling processes have improved quality while reducing production time and cost.

As a result, newer versions of chequered plates offer better grip, aesthetic uniformity, and enhanced Corrosion Resistance — all of which improve their usability and market appeal.

Evaluating Potential Challenges

While chequered plates offer a wealth of benefits, investors and contractors should be aware of a few potential drawbacks:

Weight Considerations

Steel chequered plates, though durable, are heavy. This can lead to increased transportation costs and handling complexity. Aluminum variants are lighter but tend to be more expensive.

Corrosion Risk

Although stainless steel and aluminum plates are corrosion-resistant, mild steel chequered plates may rust if not properly coated or maintained, especially in humid or coastal areas.

Fabrication Difficulty

Working with thick chequered plates may require specialized tools or cutting equipment, which can increase fabrication costs for smaller projects.

Market Trends and Future Outlook

Despite these minor challenges, the global market for chequered plates is projected to grow steadily. Reports indicate that rising investments in public infrastructure, increased emphasis on worker safety, and the expansion of logistics and warehousing facilities will continue to fuel demand.

With the UAE government investing heavily in smart cities and transport networks, chequered plates in Dubai are expected to play a pivotal role in future construction and urban development projects.

Use Cases That Highlight the Worth of Investment

To further support the decision of investing in chequered plates, let’s look at real-world applications:

Transport and Logistics Hubs

Airports and railway stations have embraced chequered plates for non-slip flooring, maintenance platforms, and baggage conveyor systems.

Oil and Gas Platforms

Chequered plates are used on offshore rigs and walkways due to their ability to resist heavy loads and corrosive elements.

Commercial Kitchens and Workshops

High-traffic commercial environments often use aluminum chequered plates for flooring due to their slip resistance and ease of cleaning.

Tips for Investing in Chequered Plates

To ensure your investment in chequered plates is both cost-effective and beneficial, consider these professional tips:

- Choose the right material based on your project needs — aluminum for lightness, steel for strength, and stainless steel for corrosion resistance.

- Work with reputable suppliers who offer material certifications and quality checks.

- Look for customization options like cut-to-size services or pre-drilled plates for easy installation.

- Compare market prices and delivery timelines to get the best value.

- Inspect for surface finish and uniformity to ensure consistency and safety.

Conclusion

So, is it worth investing in chequered plates now? The answer is a resounding yes. With their unmatched durability, safety features, and versatile applications across industries, chequered plates continue to be a vital component in modern infrastructure and industrial setups.

The market momentum, particularly in regions like Dubai, clearly indicates sustained demand driven by construction growth and safety compliance requirements. Whether you’re a contractor, builder, or industrial supplier, investing in chequered plates today is not just practical — it’s strategically sound.

For quality supply and expert guidance, trusted industry players such as SYDNEY METAL TRADING LLC offer a comprehensive range of chequered plates to meet modern project demands efficiently.

For more insightful articles related to this topic, feel free to visit: bdnews55