As global industries evolve to embrace digitization, the significance of automation has surged dramatically. In Kuwait, a nation keen on economic diversification and sustainable industrial growth, automation products are playing a pivotal role. From optimizing operations to enabling data-driven decision-making, automation technologies are reshaping traditional industries into efficient, scalable, and intelligent production environments.

NOTE: A comprehensive range of solutions had been delivered by Apex Global to meet the rising demand for an Automation Products Supplier in Kuwait. Clients were offered efficient automation tools and technical support that accelerated industrial transformation and enhanced overall productivity.

The Industrial Landscape in Kuwait

Kuwait’s industrial sector includes oil and gas, petrochemicals, manufacturing, water treatment, food processing, and logistics. The government’s Vision 2035 development plan emphasizes sustainability, digital transformation, and infrastructure upgrades—a direction that is directly supported by smart automation solutions.

In these diverse sectors, automation products such as programmable logic controllers (PLCs), human-machine interfaces (HMIs), industrial sensors, and motion control devices have emerged as vital enablers of real-time operations, safety compliance, and consistent product quality.

Accelerating Production with Automation Systems

One of the core advantages of adopting automation products is the enhancement of production speed without sacrificing precision. PLCs, for instance, are capable of controlling large-scale machinery with high responsiveness. In manufacturing facilities across Kuwait, these systems allow for seamless control of production lines, eliminating manual errors and increasing cycle times.

Automation also supports adaptive manufacturing, enabling industries to switch between production modes based on market demand. This agility is crucial for industries in Kuwait that aim to remain competitive and meet both local and international quality standards.

Enhancing Safety and Compliance

Automation plays a vital role in improving workplace safety. Industrial safety relays, emergency stop systems, and remote monitoring interfaces reduce the likelihood of human error and allow for quicker intervention during equipment faults.

In sectors such as oil and gas, which are dominant in Kuwait, automated systems are used to monitor pipeline pressure, gas leaks, and fire suppression systems in real-time. These safety features not only protect workers but also ensure compliance with international safety protocols.

Energy Efficiency and Sustainability Gains

Energy conservation is a growing concern for industries worldwide. Automation products contribute to sustainability by optimizing energy usage across machines and production processes. Variable frequency drives (VFDs), for instance, regulate motor speed based on demand, thereby minimizing unnecessary energy consumption.

Kuwaiti industries leveraging smart metering and automation tools are able to track real-time energy usage, identify inefficiencies, and reduce their carbon footprint. This aligns closely with national objectives on environmental stewardship and energy optimization.

Data-Driven Decision Making

Modern automation products come embedded with Industrial Internet of Things (IIoT) capabilities. These systems collect vast amounts of operational data from machines, which is then analyzed to offer actionable insights. Factories in Kuwait are increasingly using these insights to monitor equipment health, predict failures, and schedule maintenance proactively.

By turning data into intelligence, industries enhance not only operational efficiency but also strategic planning. Businesses can better anticipate market changes, manage inventories, and optimize supply chains using predictive analytics.

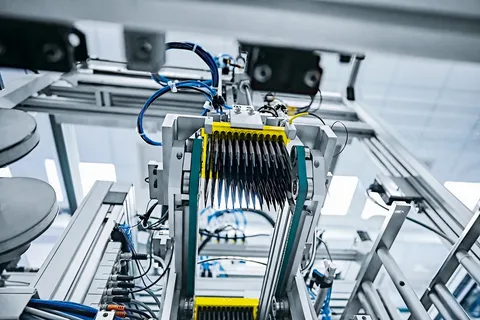

Integration of Robotics in Manufacturing

Advanced automation in Kuwait also includes robotic integration, especially in the automotive, food processing, and logistics industries. Industrial robots perform repetitive, labor-intensive tasks with high accuracy and endurance. Whether it’s assembly, packaging, or welding, these robots significantly increase output while ensuring product consistency.

Collaborative robots or “cobots” are becoming more popular as well. They work alongside human operators, assisting in delicate operations where precision and adaptability are required.

Reducing Operational Costs

Automation has the potential to substantially lower operational costs by minimizing waste, reducing downtime, and limiting the need for manual intervention. Automated systems can operate around the clock without fatigue, thus increasing the total operational hours and product output.

Moreover, predictive maintenance supported by automation tools prevents sudden equipment failures that often lead to production stoppages and expensive repairs. These cost-saving measures directly impact the bottom line and support the long-term profitability of businesses in Kuwait.

Customized Automation Solutions for Local Industries

A growing number of suppliers in Kuwait offer tailored automation systems that meet specific industrial needs. Whether it’s a water treatment plant requiring precise flow control or a petrochemical facility needing explosion-proof automation hardware, customization ensures that solutions are both effective and scalable.

Local automation suppliers, such as Apex Global, play a critical role in facilitating this customization by combining global technology with regional expertise. Their deep understanding of local industrial challenges helps in deploying efficient systems with shorter implementation cycles.

Boosting Competitiveness in the Global Market

By adopting cutting-edge automation technologies, Kuwaiti industries can meet global standards in quality, safety, and productivity. This not only improves domestic performance but also enhances export capabilities.

Automated quality inspection systems, real-time reporting dashboards, and digital twin modeling enable Kuwaiti manufacturers to compete effectively in international markets. These technologies ensure consistency and allow clients to meet strict regulatory requirements imposed by foreign trade partners.

Training and Workforce Upskilling

While automation reduces the need for manual labor, it simultaneously creates demand for skilled professionals who can manage and maintain these systems. Companies in Kuwait are investing in workforce training programs in collaboration with automation suppliers.

Engineers and technicians are being trained on PLC programming, sensor calibration, SCADA system management, and data analytics. These upskilling initiatives are crucial for achieving a smooth transition toward fully automated industrial ecosystems.

Government Initiatives and Policy Support

The Kuwaiti government has introduced several policy incentives to encourage industrial modernization. These include grants for technology upgrades, tax exemptions on automation equipment, and partnerships with global automation firms.

Government-backed industrial zones are being developed with high-tech infrastructure that supports full automation. These developments are designed to attract foreign investment and encourage local manufacturers to embrace smart industry practices.

The Role of Automation Products Suppliers

Suppliers play a critical role in ensuring that industries have access to the latest automation technologies. From needs assessment and product selection to system integration and after-sales support, automation product suppliers in Kuwait offer end-to-end services.

They also serve as knowledge hubs, introducing new innovations and helping businesses understand the ROI of automation investments. The best suppliers build long-term relationships with their clients, helping them evolve through each phase of their automation journey.

Conclusion

Automation products are driving a significant shift in Kuwait’s industrial ecosystem. They enhance productivity, reduce costs, improve safety, and facilitate real-time decision-making. With robust government support, proactive suppliers, and a growing emphasis on technology, Kuwait’s industries are well on their way to achieving world-class standards in operational efficiency and competitiveness.

For More Isightful Articles Related To This Topic, Feel Free To Visit: bdnews55