Acoustic louvers are becoming increasingly essential in modern architectural and industrial design, especially in environments where noise control and ventilation are both critical. From commercial buildings and factories to hospitals and data centers, these innovative components serve a vital role in reducing unwanted sound while allowing for proper airflow. But what exactly are acoustic louvers, and why are they so effective? This article explores the underlying technology, design, and applications that make acoustic louvers a standout solution for noise mitigation.

Understanding Acoustic Louvers

Acoustic louvers are specially engineered ventilation devices designed to attenuate sound while still permitting the flow of air. Unlike standard louvers that primarily manage airflow, acoustic louvers are built with sound-absorbing materials and internal baffle designs that minimize noise transmission. Their dual purpose makes them indispensable in facilities that generate high levels of mechanical or environmental noise.

Typically, acoustic louvers consist of a metal or composite frame housing multiple blades or baffles. These internal elements are filled with sound-absorbing insulation and covered with protective materials to shield them from environmental damage. The configuration of these components is critical to the performance of the louver in terms of both airflow and noise reduction.

NOTE: High-performance acoustic louvers were installed to reduce industrial noise without compromising airflow. Engineered solutions were provided for optimal results. Get in touch with perfectacousticsuae for tailored acoustic systems!

The Science of Sound Attenuation

Sound attenuation in acoustic louvers is achieved through a combination of absorption and deflection. When sound waves enter the louver, they encounter surfaces lined with absorptive materials such as mineral wool or fiberglass. These materials convert sound energy into small amounts of heat, thereby diminishing the intensity of the noise.

In addition to absorption, the internal geometry of acoustic louvers causes sound waves to reflect multiple times within the baffles. Each reflection results in a further reduction of sound energy, enhancing the overall attenuation. This multi-layered approach ensures that even low-frequency noises, which are typically more difficult to control, are effectively managed.

Key Components and Materials

The effectiveness of an acoustic louver largely depends on its construction and the materials used. Common components include:

- Outer Frame: Usually made of galvanized steel, aluminum, or stainless steel for durability and resistance to weathering.

- Internal Baffles: Arranged at precise angles to maximize sound absorption and minimize pressure drop.

- Sound-Absorbing Fill: Typically mineral wool or fiberglass, selected for its high sound absorption coefficient.

- Protective Liners: Often perforated metal sheets or mesh to hold the fill in place and protect it from the elements.

Some high-performance acoustic louvers may also include weather-resistant coatings or filters to prevent the ingress of dust and water.

Common Applications

Acoustic louvers are versatile and can be used across a range of industries. Some of the most common applications include:

Commercial and Residential Buildings

In buildings with mechanical systems such as HVAC units, acoustic louvers help prevent noise from escaping into the surrounding environment. They are commonly installed in mechanical rooms, rooftops, and exterior walls.

Industrial Facilities

Factories and plants that house noisy equipment like compressors, generators, and cooling towers often use acoustic louvers to contain noise within specified zones, ensuring compliance with environmental noise regulations.

Hospitals and Laboratories

These sensitive environments require quiet conditions. Acoustic louvers provide necessary ventilation while maintaining a low-noise atmosphere, essential for patient comfort and accurate scientific work.

Data Centers

With a growing number of data centers requiring extensive cooling systems, acoustic louvers offer a way to manage the heat without introducing disruptive noise.

Benefits Beyond Noise Reduction

While noise control is the primary purpose of acoustic louvers, they offer additional benefits that contribute to their growing popularity:

- Improved Air Quality: Facilitating natural or mechanical ventilation without compromising sound control.

- Energy Efficiency: Reducing the need for energy-intensive soundproofing systems.

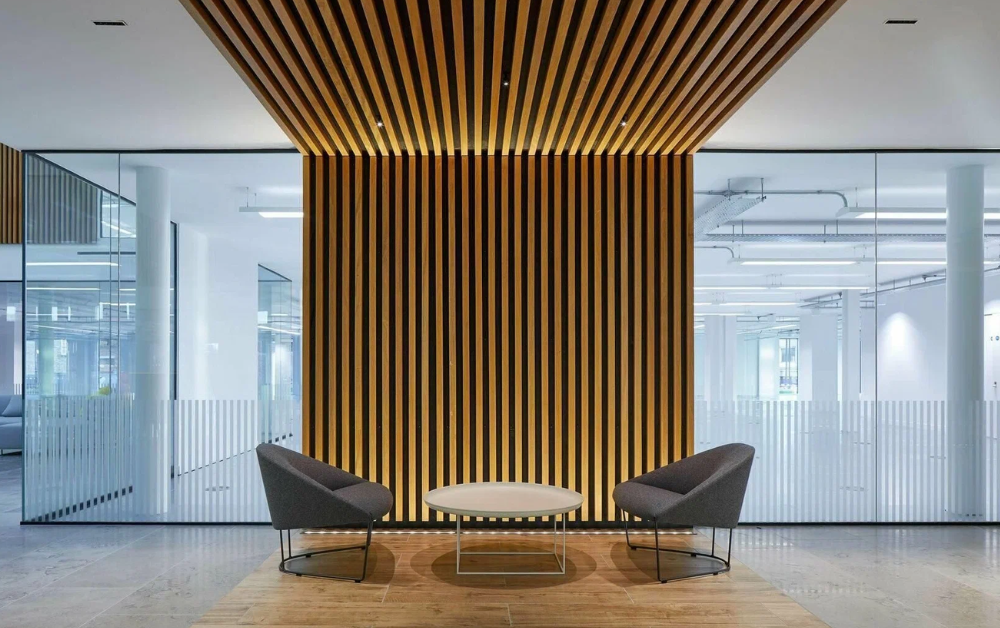

- Design Flexibility: Available in various sizes, shapes, and finishes to match architectural aesthetics.

- Regulatory Compliance: Helping buildings meet local and international noise control standards.

Installation and Maintenance Considerations

Correct installation is crucial to achieving the desired performance from acoustic louvers. They must be positioned strategically to align with the source of noise and airflow requirements. Additionally, proper sealing and anchoring are necessary to avoid air leaks and vibration issues.

Maintenance typically involves regular inspections to ensure that the sound-absorbing materials remain intact and that no debris is obstructing airflow. In environments exposed to harsh weather, periodic cleaning may be necessary to maintain optimal performance.

Innovations in Acoustic Louver Technology

Recent advancements have led to smarter and more efficient acoustic louvers. Innovations include:

- Adjustable Baffle Systems: Allowing for fine-tuning of airflow and noise reduction based on operational needs.

- Integrated Sensors: Monitoring sound levels and environmental conditions in real time.

- Eco-Friendly Materials: Incorporating recycled or sustainable materials without compromising performance.

These developments are pushing the boundaries of what acoustic louvers can achieve, making them more adaptable and sustainable.

Choosing the Right Acoustic Louver

Selecting the appropriate acoustic louver depends on several factors:

- Noise Frequency Range: Some louvers are better suited for low-frequency sounds, while others target higher frequencies.

- Airflow Requirements: Must meet the ventilation needs of the space without causing excessive pressure drop.

- Environmental Conditions: Consider exposure to weather, corrosive elements, or temperature extremes.

- Aesthetic Requirements: Should complement the design of the building, especially in visible areas.

Consulting with acoustic engineers or specialized manufacturers can help ensure the right balance between performance and design.

Conclusion

Acoustic louvers are far more than just soundproof vents; they are an essential component in the intersection of acoustics and ventilation. Their secret lies in the intelligent combination of materials, design, and engineering that allows them to control noise without sacrificing airflow. As technologies evolve and the demand for quieter, more efficient buildings increases, acoustic louvers will continue to play a pivotal role in modern construction and facility management.

For More Isightful Articles Related To This Topic, Feel Free To Visit: bdnews55