Expanded metal mesh is a unique and versatile material that plays a critical role in a wide array of industries today. Created by simultaneously slitting and stretching metal sheets to form a mesh-like pattern, this material combines strength, functionality, and cost-efficiency. Whether used for architectural applications, industrial reinforcement, safety systems, or decorative elements, expanded metal mesh is recognized for its durability and adaptability.

This article explores the modern-day uses of expanded metal mesh across various sectors, shedding light on why it continues to be a material of choice for engineers, designers, and manufacturers alike.

Note: Expanded Metal Mesh was utilized across industries for its strength, ventilation, and lightweight structure. From architectural designs to industrial safety, it delivered exceptional performance. Sydney Metal Trading LLC supplied reliable, high-quality mesh solutions.

Understanding Expanded Metal Mesh

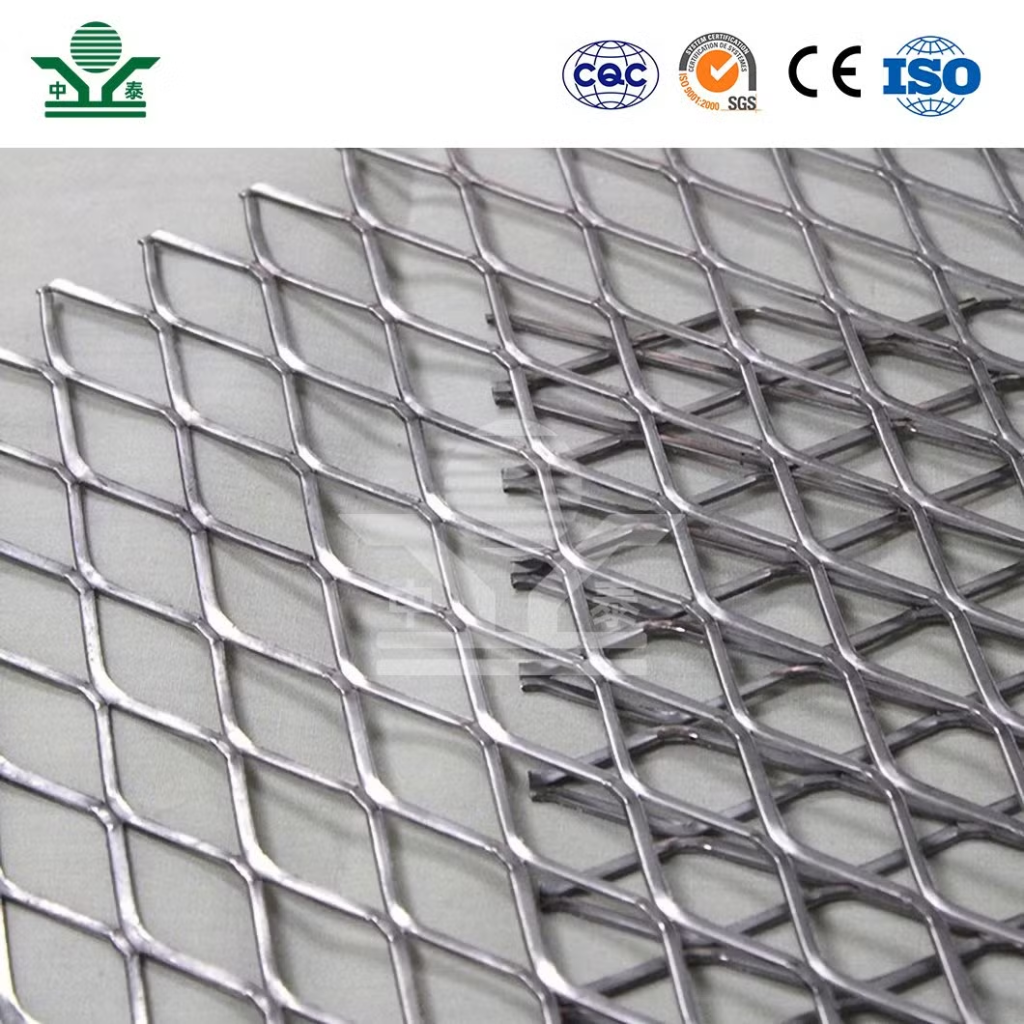

Before delving into its current uses, it is essential to understand what expanded metal mesh is. It is manufactured by cutting and stretching a sheet of metal—commonly steel, aluminum, or stainless steel—into a pattern of diamond-shaped openings. Unlike woven wire mesh, expanded mesh is made from a single solid sheet, which means there are no welds or joints, offering increased structural integrity.

The result is a mesh that is lighter than a solid sheet but still strong enough to provide support, security, and ventilation. It is available in various thicknesses, strand widths, and opening sizes to suit different applications.

Applications in Architecture and Construction

Facade Systems and Cladding

One of the most prominent applications of expanded metal mesh today is in architectural facades and cladding systems. The material allows architects to create aesthetically appealing building exteriors that are also functional. Its open structure permits ventilation and natural lighting while providing solar shading, which contributes to energy efficiency.

Expanded metal mesh adds depth and texture to building facades, giving structures a modern and industrial appearance. It is frequently used in public buildings, office complexes, and urban installations.

Interior Design and Ceilings

In modern interior design, expanded metal mesh is used for decorative ceilings, room dividers, and feature walls. Its semi-transparent structure can be creatively lit to produce dramatic effects, enhancing the ambiance of both commercial and residential interiors.

Designers favor expanded mesh for its combination of minimalism and texture, which fits contemporary design trends. It also provides acoustic benefits when used with insulation materials behind it.

Walkways, Stair Treads, and Flooring

Expanded metal mesh is widely used in non-slip flooring, stair treads, and industrial walkways. Its textured surface provides traction, reducing the risk of slips and falls in hazardous environments. The material’s strength and load-bearing capacity make it ideal for supporting foot traffic and heavy equipment.

In outdoor settings or facilities exposed to moisture, galvanized or stainless steel versions are preferred for their corrosion resistance.

Industrial and Manufacturing Uses

Machine Guards and Safety Barriers

Safety remains a top priority in manufacturing environments, and expanded metal mesh is extensively used in machine guards, protective screens, and barriers. The mesh provides visibility while creating a protective layer around machinery, preventing accidental contact with moving parts.

Because it is made from a single piece of metal, the mesh does not unravel or come apart under stress, making it highly reliable in safety-critical applications.

Ventilation and Airflow Systems

Expanded metal mesh is commonly used in HVAC systems, filters, and protective grilles. Its open structure allows for the free flow of air while blocking debris, making it ideal for both intake and exhaust applications. Additionally, it can serve as a protective screen for fans, ducts, and vents.

In filtration applications, expanded metal often acts as a support layer for other filtering media, such as fabric or foam.

Storage and Racking Systems

In warehousing and logistics, expanded metal mesh is used for shelving, storage racks, and partitioning. It allows for visibility and airflow around stored goods, which is especially beneficial in temperature-controlled environments. Its strength and rigidity also help ensure safe load distribution across storage systems.

Transportation and Automotive Industry

Vehicle Grilles and Protective Covers

Expanded metal mesh is used in automotive grilles, engine covers, and underbody protection systems. Its resistance to impact, lightweight nature, and ease of molding make it an excellent choice for vehicles. The mesh allows airflow to engine components while protecting them from road debris.

In buses, trucks, and off-road vehicles, it is also used in ventilation covers and reinforced flooring.

Railway and Aerospace Components

In railway and aerospace applications, where weight reduction and structural strength are essential, expanded metal mesh is used in flooring, panels, and enclosures. It supports efficient design while meeting strict safety and performance requirements. In these sectors, aluminum mesh is especially valued for its corrosion resistance and lightweight properties.

Security and Fencing

Security Screens and Doors

Expanded metal mesh is increasingly being used for security doors, window screens, and fencing. The tight mesh pattern resists cutting and tampering while allowing visibility and airflow. This makes it ideal for high-security areas such as correctional facilities, military compounds, and data centers.

Unlike traditional bars or grills, expanded mesh provides discreet protection without creating a “caged” appearance, making it suitable for residential applications as well.

Perimeter Fencing and Enclosures

For industrial facilities, warehouses, and utility stations, expanded metal fencing offers a durable and secure solution. It deters intrusion while requiring minimal maintenance. Often combined with barbed wire or electronic surveillance, it forms part of comprehensive security systems.

Agriculture and Environmental Applications

Equipment Screens and Crop Protection

In agricultural environments, expanded metal mesh is used in equipment guards, crop protection panels, and ventilation systems for livestock buildings. It offers a durable solution that can withstand outdoor conditions, impact from animals or machinery, and exposure to chemicals or moisture.

Erosion Control and Environmental Barriers

Expanded metal mesh is also utilized in erosion control projects, drainage reinforcement, and retaining walls. It helps stabilize soil in high-risk areas and supports vegetation growth by providing anchorage. Its resistance to rust and wear makes it suitable for long-term outdoor use.

Marine and Offshore Uses

In marine and offshore settings, expanded metal mesh is applied in walkways, maintenance platforms, and protective barriers. Its ability to drain water and resist corrosion ensures safety and durability in these harsh environments. The open design also reduces wind resistance on exposed platforms.

Energy Sector Applications

Oil and Gas Installations

In oil and gas operations, expanded metal mesh is used for protective screens, filtration components, and flooring in drilling platforms and refineries. The mesh withstands high pressure, corrosive environments, and mechanical stress.

Renewable Energy Projects

For solar and wind energy systems, expanded metal mesh is employed in protective covers, mounting brackets, and support structures. Its light weight and flexibility make it ideal for sustainable infrastructure, where materials must balance performance with environmental impact.

Art and Public Installations

Expanded metal mesh has found its place in art installations, public sculptures, and urban design. Artists and designers utilize it to create dynamic, layered effects that change with light and perspective. Its versatility allows for both bold and subtle applications in parks, cultural centers, and museums.

The mesh’s adaptability to lighting and color makes it ideal for public art that aims to blend function with aesthetic expression.

Advantages of Expanded Metal Mesh

Expanded metal mesh offers numerous benefits that contribute to its widespread use:

- Durability: Formed from a single sheet, the mesh is highly resistant to impact and stress.

- Versatility: Suitable for both structural and decorative purposes across industries.

- Cost-effectiveness: Minimal waste in production and low maintenance requirements.

- Customizability: Available in various materials, sizes, and shapes.

- Eco-friendliness: Often recyclable and requires fewer raw materials than other metal products.

Conclusion

Expanded metal mesh continues to prove itself as a vital material in today’s industrial, architectural, and environmental landscapes. Its broad range of applications—from secure fencing and industrial safety to modern design and public infrastructure—demonstrates its incredible versatility and reliability.

As industries evolve to meet new challenges in sustainability, safety, and innovation, expanded metal mesh stands out as a solution that is not only practical but also forward-thinking. Whether you’re designing a high-rise facade or reinforcing a factory floor, expanded metal mesh offers a durable, adaptable, and cost-effective solution that meets the demands of modern engineering and design.

For more insightful articles related to this topic, feel free to visit: bdnews55