When it comes to hardware accessories, one crucial yet often overlooked category is restraints. These components play a pivotal role in ensuring safety, stability, and functionality across a wide range of industries. Whether in construction, automotive, or electronics, restraints provide critical support and help prevent damage or failure. In this blog, we will explore what hardware restraints are, their different types, and why they are indispensable in various applications.

What Are Hardware Restraints?

In the context of hardware accessories, restraints refer to devices or components designed to restrict, secure, or control the movement of objects. They are used to hold equipment in place, prevent unwanted motion, and safeguard components against external forces like vibration, impact, or environmental stress.

Types of Hardware Restraints

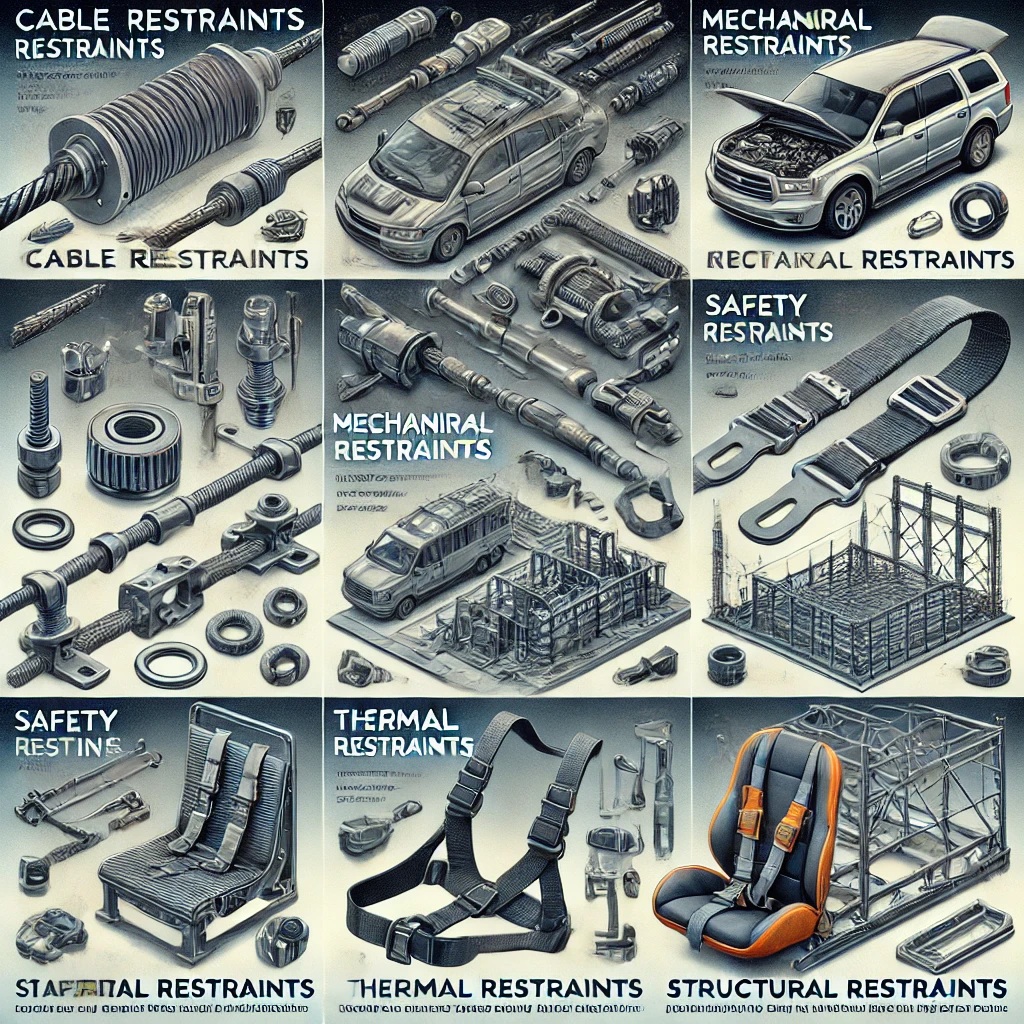

Hardware restraints come in various forms, each suited for specific applications.Below are some of the most frequently used types:

- Cable Restraints

- Used to secure electrical and mechanical cables.

- Prevents cables from shifting, tangling, or being damaged.

- Mechanical Restraints

- Includes clamps, brackets, and fasteners.

- Provides mechanical support and stability to moving or stationary parts.

- Safety Restraints

- Used in environments where safety is a priority (e.g., seat belts, harnesses).

- Protects users and equipment from accidental movement or displacement.

- Thermal Restraints

- Helps manage heat-induced expansion or contraction.

- Often used in industrial applications where temperature changes affect hardware.

- Structural Restraints

- Reinforces frameworks to prevent movement under stress.

- Essential in building construction and heavy machinery applications.

Importance of Restraints in Hardware Accessories

Restraints are vital for maintaining the integrity and longevity of equipment and structures. Here are a few reasons why they are indispensable:

- Enhanced Safety

- Restraints protect both equipment and users from accidents due to uncontrolled movement.

- Improved Durability

- By minimizing vibrations and preventing movement, restraints extend the lifespan of components.

- Operational Stability

- Ensures that hardware functions smoothly without misalignment or displacement.

- Compliance with Standards

- Many industries have strict regulations requiring the use of specific restraints to maintain safety standards.

- Damage Prevention

- Securing sensitive components with restraints reduces the risk of physical damage or wear.

Choosing the Right Hardware Restraints

Selecting the appropriate restraint for your application involves considering several factors:

- Load Capacity: Ensure the restraint can withstand the maximum load it will encounter.

- Material: Choose materials suited for the environment (e.g., corrosion-resistant for outdoor use).

- Flexibility: Some applications require rigid restraints, while others need flexible or adjustable options.

- Compliance: Verify that the restraints meet industry safety and quality standards.

Final Thoughts

Restraints in hardware accessories are more than just simple securing devices; they are critical to ensuring safety, stability, and operational efficiency. By understanding their types and applications, you can make informed decisions to enhance the reliability and safety of your projects.

Whether you are working on a construction site, assembling electronic devices, or managing industrial equipment, the right hardware restraints can make a significant difference. Always choose high-quality restraints that align with your specific needs to ensure optimal performance and longevity.