Introduction

Servos are a crucial component in robotics and automation, providing precise control over motion and positioning. From robotic arms to radio-controlled cars and industrial machines, servos play a key role in achieving smooth and accurate movements. This blog explores the fundamentals of servos, their types, applications, and how they work.

What is a Servo?

A servo, or servo motor, is a rotary or linear actuator that allows precise control of angular or linear position, velocity, and acceleration. It consists of a motor, a position feedback sensor, and a control circuit. The servo receives signals from a controller to adjust its position accordingly.

Types of Servos

Servos come in various types, each designed for specific applications:

- Positional Rotation Servo – These servos rotate within a fixed range (usually 0 to 180 degrees) and are commonly used in robotic arms and steering mechanisms.

- Continuous Rotation Servo – Unlike positional servos, these can rotate continuously in either direction, making them ideal for wheeled robots and conveyor systems.

- Linear Servo – Converts rotary motion into linear motion, often used in industrial automation and actuators.

How Does a Servo Work?

A servo operates based on a pulse width modulation (PWM) signal, which determines its position. The controller sends pulses at different widths, and the servo interprets these signals to move to the desired angle. The feedback sensor continuously monitors the position and adjusts accordingly for precision.

Applications of Servos

Servos are widely used in various fields, including:

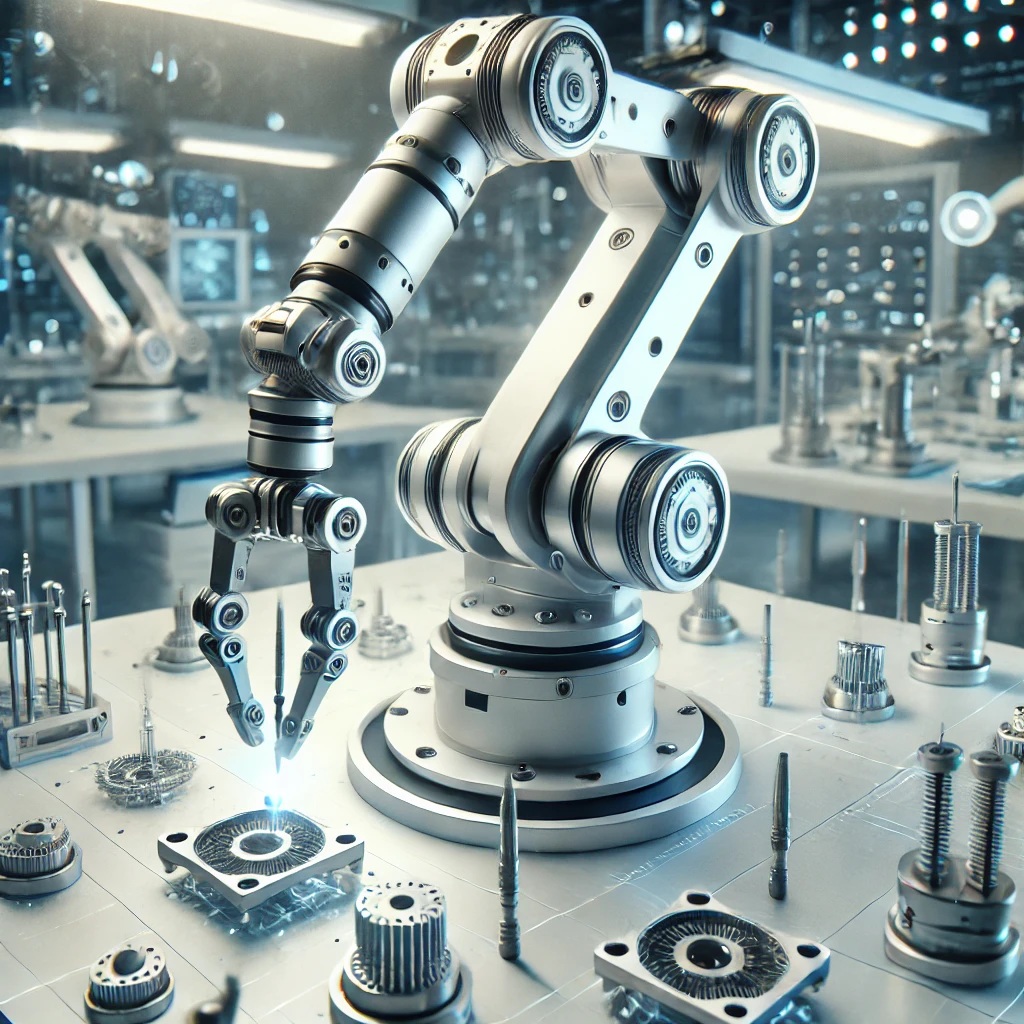

- Robotics – Essential for joint movement in humanoid robots and robotic arms.

- Aerospace – Used in control surfaces of aircraft, such as rudders and ailerons.

- Automotive – Found in automatic window mechanisms and braking systems.

- Industrial Automation – Helps in conveyor belt systems, CNC machines, and precision tooling.

- Radio-Controlled Vehicles – Used in RC cars, boats, and drones for steering and control.

Choosing the Right Servo

Selecting a servo depends on several factors:

- Torque – Measured in kg-cm, determines how much force the servo can exert.

- Speed – The time it takes to move to a specific position.

- Voltage and Power Requirements – Ensures compatibility with your project.

- Size and Weight – Important for compact applications like drones and robotic arms.

Conclusion

Servos are indispensable in robotics and automation, providing precise and reliable movement. Understanding their functionality and applications helps in selecting the right servo for your project. Whether you are building a robot, automating a machine, or designing a drone, servos are a vital component for smooth and efficient motion control.

Visit Here: https://makerbazar.in/